Cambia lingua :

Laboratorio di prova igus: ricerca e sviluppo su 5.500 m²

Testati, collaudati, calcolabili

In igus, puntiamo a sviluppare materiali e prodotti innovativi che offrano ai nostri clienti un reale valore aggiunto. Per raggiungere questo obiettivo, cerchiamo di continuare a migliorare noi stessi e le nostre soluzioni, seguendo il motto: Tech up, Cost down !

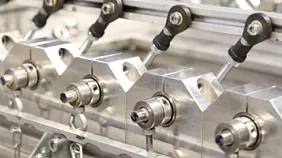

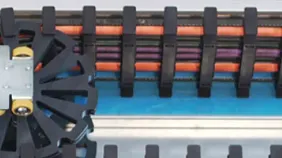

I nostri prodotti durano a lungo prolungando la durata delle macchine e applicazioni, non richiedono manutenzione e permettono di ridurre i costi. Per i nostri ingegneri, la qualità e la sicurezza dei componenti, la loro capacità di carico e la loro durata sono aspetti fondamentali in fase di sviluppo. Ogni prodotto igus viene accuratamente testato prima di essere immesso sul mercato. A questo scopo, dal 1985 abbiamo un laboratorio interno: non solo è il più grande del settore per i tribopolimeri in termini di superficie, ma anche quello con il maggior numero di test sui prodotti. Il laboratorio è ciò che ci permette di offrire una garanzia fino a quattro anni.

Questa pagina fornisce informazioni dettagliate sul nostro laboratorio di test.

Cosa viene testato?

Complessivamente il laboratorio di test per applicazioni e materiali si estende su oltre 5.500 m². Ogni divisione aziendale ha il proprio laboratorio di test, e alcuni prodotti vengono testati insieme:

- 2.000 m² di area esterna per testare catene portacavi e cavi chainflex con corse molto lunghe

- 1.500 m² di area di prova per cavi chainflex nelle nostre catene portacavi

- 300 m² di area di prova per cuscinetti a strisciamento iglidur, guide lineari drylin e Low Cost Automation, quest'ultima in parte in condizioni reali nel controllo qualità

- 200 m² di area di prova per igus:bike e componenti per biciclette

- NOVITÀ: 1.500 m² di area di prova nel nuovo capannone

Per sviluppare nuovi prodotti compatibili con le camere bianche in modo più rapido, gestiamo un nostro laboratorio con un sistema di classe ISO 1 in collaborazione con il Fraunhofer IPA. Un area di prova esterna , un laboratorio per prove di rumorosità e la camera climatica a -40 °C, temuta dai dipendenti igus, completano il laboratorio. Per ottenere condizioni il più possibile realistiche, testiamo anche le applicazioni dei clienti ed eseguiamo test standard di settore.

Testiamo anche il tuo caso applicativo

Non hai il tempo o l'attrezzatura per eseguire le prove ma, prima di scegliere, vorresti sottoporre il materiale ad un test nella tua applicazione specifica?Oppure hai un'applicazione insolita e sei alla ricerca di una soluzione adatta? Nessun problema. Testiamo la tua applicazione nel nostro laboratorio e usiamo il nostro know-how per trovare la miglior soluzione per te. Che si tratti di cuscinetti a strisciamento, catene portacavi, cavi flessibili, tecnologia lineare, semilavorati o sistemi di automazione a basso costo.

Quanti test vengono eseguiti nel laboratorio igus?

Ogni anno, sulle nostre 742 stazioni di prova, viene eseguito un numero impressionante di test e controlli sui materiali:

- Oltre 15.000 test in totale, di cui circa 4.000 su catene portacavi e cavi chainflex e circa 11.000 sui prodotti dry-tech (con rotazioni, oscillazioni, movimenti lineari, a caduta, riscaldati, sott'acqua, ecc.).

- 10 miliardi di cicli su catene portacavi

- 3.500 cavi testati

- 1.000 test personalizzati

- Fino a 800 test eseguiti in parallelo

Che fine fanno i dati dei test?

I dati ricavati dai test non vengono utilizzati solo per lo sviluppo dei prodotti. Dal 2001 sviluppiamo innovativi strumenti online e, dal 2016, smart plastics con sensori , prodotti basati sul database dei risultati dei nostri test di laboratorio. Questi strumenti consentono di determinare in modo semplice e veloce la convenienza e la sicurezza dei nostri prodotti. Ciò offre ai nostri clienti un elevato livello di trasparenza e consente loro di trovare la soluzione economica e funzionale al loro problema. Mettiamo a disposizione dell'utente più di 40 tool gratuiti, tra cui i calcolatori di durata, i configuratori per il confronto dei prodotti, gli strumenti di selezione Product Finder, i configuratori CAD, nonché il sistema di manutenzione predittiva con i.Cee.

Tour virtuale alla scoperta del laboratorio

Con il tour virtuale puoi girare nel laboratorio, comodamente, da casa o seduto alla scrivania. Basta cliccare sul pulsante qui sotto, selezionare l'area da visitare nella home page e seguire le frecce per esplorare ogni angolo del nostro laboratorio. Clicca sui numeri per maggiori informazioni sul prodotto testato.