Changer de langue :

Energy chains, cables and heavy-duty bearings for port and intermodal cranes

Durable and networked products for long travels and high loads.

Products for harbour and intermodal cranes

Energy chains for cranes

Safe energy supply systems especially for cranes: from medium travels on RTG or RMG cranes to high loads and travel lengths of up to 1,000 metres.

Learn more

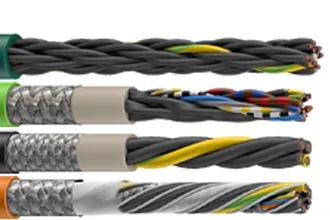

Cables for cranes

Tested, UL-certified and UV-resistant cables with service life guarantee for very long travels and tight bend radii on cranes.

Learn more

Heavy-duty bearings for cranes

Lubrication-free and maintenance-free heavy-duty and fibre composite plain bearings for the undercarriage and other highly stressed bearing points on cranes.

Learn more

Sensor technology for cranes

Prevent costly and time-consuming crane breakdowns by using networked products with sensors for condition monitoring and predictive maintenance.

Learn moreEnergy chains for harbour cranes and intermodal cranes

Unplanned downtimes must not occur at any time on harbour or intermodal cranes. This places special responsibility on the cable guide on the crane. This is because a break in the trailing cable, the cable guided in an energy chain or a defect in the cable guide itself will inevitably bring the crane operation to a standstill.

At the same time, these systems must be able to handle heavy loads over travels of over 1,000 metres without any problems.

Such risks can be minimised with special energy chains for cranes. Thanks to the development of specialised solutions such as the roller energy chains, even very long travels are possible with low drive power. This also reduces wear and maintenance costs. And thanks to optional sensor technology, the safety of the chain and cable can be further increased.

P4HD - The e-chain with the longest service life

Energy chain sample

Request a sample today: P4HD.56R

We want 15 years of service life for e-chains on cranes. This can be found in our development goals and specifications for the P4HD family.

Sensors and accessories for energy chains

The future of STS cranes and the energy chains

Triple-E container ships and STS cranes

STS cranes are changing. This is because ever larger container ships (Triple-E) will require even larger cranes in the future. You can find out exactly how this will affect STS cranes and the energy chain here.

Cables for harbour cranes and intermodal cranes

Cables that run in the energy chain on the crane are subject to high mechanical stress, just like trailing cables. The long travels and tight bend radii inevitably lead to cable stress. For this reason, we test our chainflex cables in 700 experiments each day in our in-house test laboratory. This enables us to issue a 4-year guarantee on all cables. Incidentally, all our TPE cables come with UL approval and are UV-resistant.

Your advantages with chainflex cables

UL-certified

We also offer a UL (Underwriters Laboratories) cable for every chainflex cable type.

UV-resistant

Suitable for outdoor applications: our cables are all UV-resistant.

Guarantee

Thanks to our daily laboratory tests at chainflex cables, we offer a 4-year guarantee without hesitation.

Learn more

Discover all cablesHigh-load bearings for harbour cranes and intermodal cranes

igutex composite plain bearings consist of a robust glass fibre fabric as outer shell and an inner layer optimised for optimum friction behaviour. This makes them suitable for high loads and yet they are lubrication-free and maintenance-free. This means that maintenance costs and the risk of incorrect lubrication can be avoided.

Heavy-duty bearings in detail

Heavy Duty brochure

What materials are available for heavy-duty bearings? How does igutex save bearing lubrication? And what do the load tests in the laboratory show? Find out all this and more in our Heavy Duty brochure.

Sensor technology for harbour cranes and intermodal cranes

Sensors on the energy chain or the cables on the crane guarantee a high degree of safety and reliability, especially on long travels. On large structures and long energy chains, a cable break or defect in the energy chain is not quickly detected. Added to this is the maintenance time. On busy container terminals in particular, such failures can quickly become very costly. Such problems can be avoided with the i.Sense and i.Cee sensors for monitoring and predictive maintenance of the chain or cable.

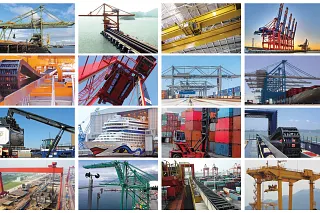

Application examples. Here customers trust in energy chains.

And many more success stories ...

STS, ASC, RTG, RMG, shipyard crane, indoor crane. Our energy chains can be used practically anywhere. We will show you what this can look like in practice using selected success stories:

User reports: Harbour and intermodal cranes

User reports: Indoor cranes

User reports: Shipyard cranes

User reports: Bulk goods cranes

System comparison - e-chain vs. festooning, motorised cable reel and busbar system

Tested for use on cranes - in the industry's largest test laboratory

With travels of several hundred metres, we don't want to leave anything to chance. Our energy chains and cables are therefore subjected to daily endurance tests on special test rigs for industries such as the crane sector. For example, on our outdoor test facility with a simulated travel distance of up to 400m for our roller energy chains and chainflex cables. Here you can find out more about our test laboratory.

Brochures for the crane industry

Conseil

Je me réjouis par avance de répondre à vos questions

igus® Schweiz GmbH+41 62 388 97 97Ecrire un e-mail

Conseil technique

Consultation vidéo via Microsoft Teams :

Réservez votre rendez-vous pour une consultation vidéo via MS Teams ici.

Consultation par Chat :

Lundi - jeudi : 8 - 17H

Vendredi : 8h - 16H30

Consultation en présentiel :

Lundi - Jeudi : 8 - 17H

Vendredi : 8 - 16H30