Changer de langue :

0 lubrification, 0 coût, 0 souci avec "GO ZERO"

Qu'est-ce que "GO ZERO"?

Les plastiques en mouvement sont des polymères hautes performances qui sont utilisées partout dans l'industrie et que les utilisateurs n'ont plus besoin de lubrifier après le montage.

Cela signifie que l'on ne fait pas seulement l'économie de graisses et d'huiles coûteuses. Les clients économisent également du temps d'entretien, des frais de personnel, le risque d'une lubrification erronée ou insuffisante, les temps d'arrêt des installations ainsi que les substances nocives qui se répandent dans le champ ou dans l'écoulement. Nous appelons cela : "GO ZERO"

Ces 3 secteurs profitent déjà de "GO ZERO"

Technique agricole

Lem ken économise ainsi 22 points de graissage par cultivateur.

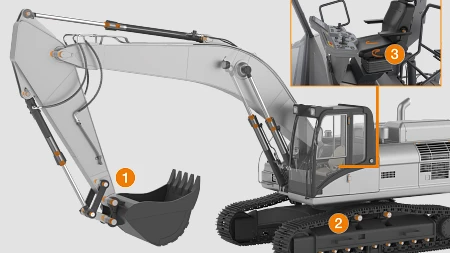

Machines de construction

Huppen kothen économise ainsi 220 opérations de maintenance par mini-pelle.

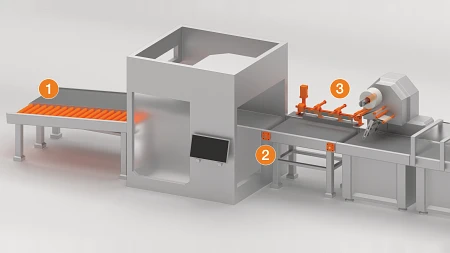

Secteur des boissons

Heineken Brasil économise ainsi un équivalent en CO2 jusqu'à 28 tonnespar an.

Livre blanc : Étude "Schmierfrei" de la RWTH Aachen et tous les cas d'utilisation

Dans ce livre blanc, nous montrons quels secteurs et quelles entreprises utilisent déjà avec succès une technique de stockage sans lubrification et sans entretien et à quelle hauteur ils profitent des économies réalisées.

Parmi eux : Heineken Brasil (technique des boissons), KettenWulf (technique d'entraînement et de manutention) ou Rockinger (technique agricole).

D'autres thèmes seront abordés :

- Quel est le coût de la lubrification ?

- Coûts de la lubrification pour l'industrie et l'environnement

- Comment fonctionnent les paliers lisses sans lubrification ?

- Conditions d'utilisation des paliers lisses sans lubrification

Lemken économise ainsi 22 points de graissage par cultivateur.

La société Lemken GmbH et Co. KG

L'entreprise s'est entre autre spécialisée dans la fabrication d'outils agricoles. C'est le cas du Karat 9, un cultivateur intensif dont les dents peuvent atteindre 30 centimètres de long. Afin de ne pas endommager l'outil, les dents s'écartent lorsque la force exercée est trop importante par exemple à cause de pierres dans le sol.

Le problème

Pour garantir le mouvement d'évitement, des paliers métalliques ont été utilisés sur toutes les dents. Les paliers métalliques devaient toutefois être graissés chaque jour pendant une heure. Si cela n'avait pas été fait, le manque de lubrification aurait entraîné de la corrosion et de l'usure.

La solution

Les paliers iglidur utilisés aujourd'hui fonctionnent entièrement sans lubrification externe, car le matériau contient des lubrifiants solides autolubrifiants. Cela permet non seulement à l'agriculteur d'économiser du temps par la suite ? il profite également de la grande capacité d'absorption des forces des paliers, de leur moindre sensibilité à la saleté et d'une durée de vie accrue des paliers lisses.

Et si chaque cultivateur en Allemagne serait équipé d'une technique de stockage sans lubrification?*.

invert_colors_off

600.000 €

Coûts de lubrification économisés

person

2.397.940 €

Coûts de personnel économisés

access_time

110 250 heures

Temps de maintenance économisé

public

47 618 kg

Équivalent en CO2économisé

local_drink

2.600.000 l

Moins d'eau douce contaminée par des polluants

nature

19 268 ha

Moins de sol pollué par le rejet de polluants

Plus d'informations à ce sujet ?

Vous pouvez consulter les chiffres détaillés dans l'étude.

Quels sont les autres potentiels sans lubrification dans l'industrie agricole ?

1 Réglage de l'écran de la cabine

Avec un rail de guidage courbé sans lubrification dans la cabine du tracteur.

2 Protection contre l'usure de l'embrayage

Avec utilisation sans lubrification sur l'attelage de remorque.

3 Guidage de câbles pour pulvérisateur

Avec une chaîne porte-câbles robuste pour un guidage sûr des fluides en présence de poussière et de saleté.

Huppenkothen économise ainsi 220 opérations de maintenance par mini-pelle par an.

Seuls quatre points d'appui à la jonction entre le balancier et le godet de la pelle, remplacés par des paliers en polymères sans lubrification, permettent à l'utilisateur d'économiser 220 opérations de maintenance et 36,7 heures d'entretien par machine et par an.

La société Huppenkothen GmbH

La société est un fournisseur de pelles compactes, de mini-pelles et d'autres petits engins et véhicules de chantier.

Le problème

Sur les excavatrices, les points d'appui entre le bras et le godet sont soumis à des forces élevées et à des influences environnementales rudes. Dans ce cas, il est encore souvent courant d'utiliser des douilles en acier qui doivent être lubrifiées quotidiennement pour garantir un fonctionnement sans problème et à faible usure.

La solution

Quatre paliers sans lubrification en polymère haute performance remplacent les paliers métalliques à la jonction entre le manche et le godet. Ils permettent non seulement d'économiser 220 entretiens par an, mais aussi d'épargner à l'utilisateur des frais élevés de graisse. De même, le risque de manque ou d'erreur de lubrification diminue.

Et si chaque pelleteuse en Allemagne serait équipée d'une technique de stockage sans lubrification?*.

invert_colors_off

1.610.400 €

Coûts de lubrification économisés

person

14.607.520 €

Coûts de personnel économisés

access_time

671 610 heures

Temps de maintenance économisé

public

116.189 kg

Équivalent en CO2économisé

local_drink

2.600.000 l

Moins d'eau douce contaminée par des polluants

nature

19 268 ha

Moins de sol pollué par le rejet de polluants

Plus d'informations à ce sujet ?

Vous pouvez consulter les chiffres détaillés dans l'étude.

Quels sont les autres potentiels d'absence de lubrification dans les machines de construction ?

1 Paliers dans le système de bras

Par exemple avec des paliers en polymère iglidur G pour un mouvement du bras sans lubrification.

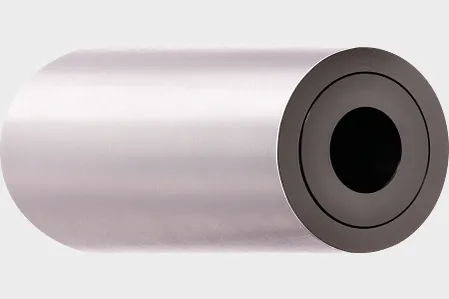

2 Points d'appui dans le châssis

Avec des paliers pour charges élevées en matériau composite renforcé par des fibres, entièrement exempts de lubrification et d'entretien.

3 Passage des câbles dans le siège

Avec une chaîne porte-câbles en polymères robuste et sans corrosion pour un guidage sûr des fluides.

Heineken Brasil économise ainsi un équivalent CO2 de jusqu'à 28 tonnes par an.

En changeant 600 paliers dans le système de transport d'une seule filiale de Heineken, le groupe économise déjà un équivalent CO2 de180 kgpar an.

Heineken Brésil

Elle est la filiale brésilienne d'un total de 160 établissements de la marque de brasserie mondialement connue Heineken.

Le problème

Dans les installations d'embouteillage modernes, jusqu'à 70.000 bouteilles peuvent être remplies par heure. Ce processus nécessite un grand nombre de pièces mobiles, par exemple dans la technique de convoyage. Jusqu'à présent, Heineken Brasil devait régulièrement contrôler et graisser les points de graissage de 600 paliers radiaux dans les convoyeurs.

La solution

Entre-temps, des roulements en polymère sont utilisés dans la technique de convoyage. Lors des opérations de maintenance, il ne sera plus nécessaire à l'avenir de les lubrifier ou de les entretenir. Heineken Brasil économise ainsi 1.560 heures de maintenance par an et 2.815,49 € de frais uniquement pour les graisses économisées.

Et si chaque filiale de Heineken utilisait une technique de stockage sans lubrification dans le domaine de la manutention?*.

invert_colors_off

450.478 €

Coûts de lubrification économisés

person

5.428.800 €

Coûts de personnel économisés

access_time

249 600 heures

Temps de maintenance économisé

public

28 814 kg

Équivalent en CO2économisé

local_drink

75.000.000 l

Moins d'eau douce contaminée par des polluants

nature

546 500 ha

Moins de sol pollué par le rejet de polluants

Plus d'informations à ce sujet ?

Vous pouvez consulter les chiffres détaillés dans l'étude.

Quels sont les autres potentiels d'absence de lubrification dans la technologie des boissons ?

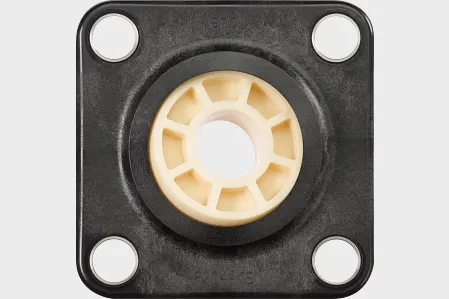

1 Roulement à billes

Avec des rouleaux de renvoi xiros pour des bandes transporteuses sans lubrification.

2 Stockage de bandes

Avec des paliers appliques igubal sans entretien pour un fonctionnement à sec.

3 Réglage des rives

Avec des réducteurs Apiro modulaires et économiques.

*Approches pour les mises à l'échelle :

Technique agricole

- env. 37.500 machines et appareils pour le travail du sol et l'entretien en DE sont produits chaque année > 20 % dont des cultivateurs

- Hypothèse d'une durée de vie de 15 ans et production annuelle de 500 cultivateurs avec paliers lisses.

- Coûts salariaux moyens des employés DE : 45.240 € á 2.080 heures par an

Machines de chantier

- env. 91.500 pelles à godets dans l'UE, > 20 % en DE, > 18.300 pelles à godets avec paliers radiaux

- Acceptation d'environ 80,52 tonnes de lubrifiant

- Coûts salariaux moyens des employés DE : 45.240 € á 2.080 h. par an

Technique des boissons

- Plus de 160 sites Heineken avec utilisation de convoyeurs dans le monde entier, économie d'environ 20 tonnes de lubrifiant.

- Coûts salariaux moyens des employés DE : 45.240 € á 2.080 heures par an