Change Language :

Hydraulischer A-Frame mit maximaler Bewegungsfreiheit

Steckbrief

Was wurde benötigt:

Gleitlager für die Schwenkkinematik eines A-Frames

Anforderungen:

Selbstschmierende und wartungsfreie Gleitlager, die witterungsbeständig und für hohe Lasten geeignet sind

Branche:

Offshore-Industrie

Erfolg für den Kunden:

Wartungsfreie und korrosionsfreie Lagerstellen, kostengünstige, nach Maß gefertigte Gleitlager

Bewegungsradius von 180°

Die Firma Ship & Yacht Engineering Ltd. ist seit Jahren spezialisiert auf die Leitung und Umsetzung komplexer Projekte im Schiffsbau und in der Meerestechnik. Ihr Gründer und Geschäftsführer, Erik Hofmann, entwickelt von Rampen bis hin zu Kreuzfahrschiffen alles für den Schiffsbau. Bei seiner Zusammenarbeit mit verschiedenen Reedereien wurde er immer wieder auf die Nachteile aufmerksam, die A-Frames bislang mit sich brachten.

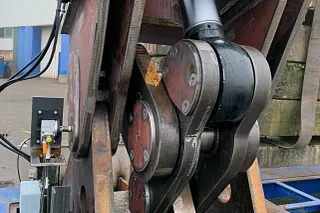

Daraufhin entwickelte er einen A-Frame mit einer wartungs- und schmierfreien Schwenkkinematik, die einen Bewegungsradius von 180° ermöglicht: dem sogenannten Linkage System. Um die Lagerstellen der Kinematik schmierfrei zu halten und Wartungen auf ein Minimum zu reduzieren, setzt Hofmann dabei auf iglidur® Gleitlager.

Im Hafen des ostfriesländischen Leer steht der neuartige A-Frame von Erik Hofmann, der zunächst wie jeder andere zu sein scheint. Auf den zweiten Blick fällt jedoch eine entscheidende Sache ins Auge: Dieser A-Frame hat, im Gegensatz zu anderen hydraulisch betriebenen A-Frames, keine außenliegenden Zylinder. Genau hier liegt der große Vorteil von Hofmanns Entwicklung. Das Hebesystem wird mit Hilfe des Linkage Systems gekippt. Die Zylinder und die spezielle Schwenkkinematik sind im Rahmen des A-Frames verbaut und ermöglichen einen Bewegungsradius von 180°.

Geeignet für bis zu 20 Tonnen Schwenklast

Von der Klassifikationsgesellschaft abgenommen ist der A-Frame von Ship & Yacht Engineering Ltd. bereits und kann, abhängig vom Schwenkwinkel, Lasten bis 20 Tonnen heben. Nun wird er auf einem Forschungsschiff von Fugro, dem weltweit führenden Geodatenspezialisten, verbaut und soll dort z. B. Magnetometer ins Wasser lassen und wieder rausheben.

Damit die Schwenkkinematik auch auf hoher See und unter rauen Witterungsbedingungen störungsfrei funktioniert, suchte Hofmann für seine Schwenkkinematik selbstschmierende, wartungsfreie Gleitlager, die kostengünstig sein sollten. Bisher habe er Bronzebuchsen eingesetzt. Durch die Witterung wurde jedoch das Fett ständig aus den Lagerstellen gespült, sodass permanent neues Fett nachgepumpt werden musste, um Mangelschmierung und Korrosion zu verhindern, berichtet der Schiffsbauingenieur.

Der Selbstschmiereffekt verhindert Mangelschmierung

Durch eine Empfehlung stieß Hofmann auf die igus® SE & Co. KG aus Köln, einen Entwickler und Hersteller von schmierfreien Hochleistungskunststoffen. Deren Gleitlager aus dem Werkstoff igutex TX1 werden nun in der Schwenkkinematik des A-Frame eingesetzt. Sie wurden extra für Anwendungen mit hoher Last entwickelt, reduzieren Wartungsaufwand auf ein Minimum und benötigen keine zusätzliche Schmierung.

„Unsere Gleitlager enthalten inkorporierten Festschmierstoff, der millionenfach in Kammern im Werkstoff enthalten ist. So ist immer ausreichend Schmierstoff vorhanden, um die Lagerstelle zu schmieren. Eine Mangelschmierung kann so gar nicht erst auftreten“, erläutert Uwe Sund, Produktmanager für iglidur® Schwerlastlager. Da kein zusätzliches Schmiermittel notwendig ist, kann komplett auf eine manuelle Schmierung bzw. auf ein automatisches Schmiersystem verzichtet werden.

Hier geht es zu den eingesetzten Produkten

igutex TX1 Gleitlager

Beratung

Gerne beantworte ich Ihre Fragen auch persönlich

igus® Schweiz GmbH+41 62 388 97 97E-Mail schreiben

Beratung

Video-Beratung per Microsoft Teams:

Buchen Sie Ihren Termin für eine Video-Beratung per MS Teams hier.

Chat-Service:

Montag – Donnerstag: 8 – 17 Uhr

Freitag: 8 – 16:30 Uhr

Persönlich:

Montag – Donnerstag: 8 – 17 Uhr

Freitag: 8 – 16:30 Uhr